Do I really need a Big Bore kit?

How will these parts affect the power output of my Harley-Davidson motorcycle?” These are two of the most frequently asked questions we receive on the Biker Helpline.

Unlike any Harley-Davidson(R) motorcycles in the past, when engineers started designing the Twin Cam 88 engine (first seen in 1999), they over-built the cases and flywheels to support torque and horsepower increases. For the first time in history, Harley motorcycles had oversize pistons, cylinders, heads, and cams ready to be installed at the same time a new engine was introduced.

These relatively easily installed big bore kits are the most common starting points for high-performance modifications.

Our project bike was sitting in the garage with the only unmodified component being the original Twin Cam engine, so we set out to rectify this oversight. Although we have always used Harley’s factory part kits, we recently had the opportunity to install Motorcycle Garage’s Stage 3 Big Bore Kit. The kit consists of high-lift cams, ported heads, cylinders, CP pistons and rings, an S&S gear drive, adjustable pushrods, ignition, and gaskets. We also added Harley’s roller rocker arms and a set of Jim’s Big Axle tappets.

It has been Bill’s experience over the years that stock tappets cannot take the rpm increase or added

load pressures of performance valve springs. The heads also are machined for compression releases because, without them, the high compression will load the starter and destroy it. With compression releases installed, the motorcycle will start easier than stock.

We also swapped out the stock cast cam support plate and updated it with a billet aluminum plate. This thicker, stronger plate allows for a more stable cam plate with no tension on the camshafts. Finally, we updated the oil pump to the now-standard 2007-style Harley-Davidson oil pump (introduced in the ’06 Dyna models) to flow and scavenge more oil within the engine.

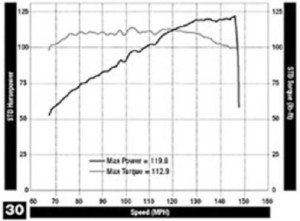

Installation of our kit takes around a dozen hours to complete, and has transformed a stock 1450cc, 65 horsepower engine into a 1550cc powerhouse. After breaking in the engine for 500 miles, we strapped it down and measured the engine output on our CycleDyn dynamometer.

After a few runs on the dyno, our final figures were 118 horsepower and 108 ft/lbs of torque. This is

bolt-on power at its best. The Harley engine is as smooth as stock, pulls cleanly all the way from idle, still gets decent fuel economy, and is almost capable of pulling stumps from the ground.

The Harley-Davidson(R) motor has been transformed. Rolling away from stop signs requires almost no throttle application and passing automobiles on back roads is now an effortless top gear roll-on. While you might not “need” a big bore kit, it is one of the most cost-effective ways to increase your Harley-Davidson’s performance, and you will be paid back with fun every time you twist the throttle. And isn’t that part of what riding a motorcycle is all about?